As I mentioned before, I am building one bent to "see how it goes". I've worked with a sawyer in town in the past, and he does a great job. He's a very careful guy, and his prices are reasonable. I placed the order a few weeks ago now, and just got the beams back to the shop.

The photo at left shows my logs before they were sawn. The logs are white pine, very common in VT, and easy to work with, except for the pitch that sticks to everything.

Since i don't have a pickup truck, and these beams are a little too heavy for the roof rack of a Corolla, i was lucky enough to enlist my uncle Alan in transporting the finished beams.

All the beams in this batch are 10"x10", and heavy as hell. Unfortunately, we had an ice storm just before we got to pick up the beams. They were all covered in ice, and slipping all over the place.

When we got the beams back to the shop, we put them on an old haywagon, and covered them with a tarp.

Since the beams are so big, they would be to tall to work on efficiently on a regular sawhorse. So I built these little ones that are about 24" off the ground.

they're made out of maple and seem pretty strong. With beams on top they're the perfect height to work at, so i don't have to stoop. Gotta go easy on the spine- It'll be plenty sore moving the beams around, haha.

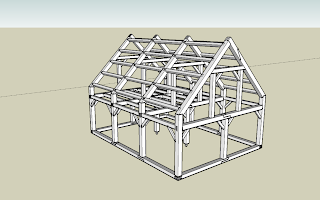

Here's the finished product carrying the two beams I intend to be the posts of bent number one.

The shop isn't heated, but it's still a little above freezing in there. A few days and hopefully these first two beams will be dried out, and ready to work on.